In the realm of steel fabrication businesses, the fusion of industrial laser solutions marks a new era of efficiency. Dive into exploring industrial laser solutions to witness precision and productivity merging seamlessly.

The well-being of steel fabrication enterprises hinges on the effectiveness of these advanced technologies, promising innovation and practicality. Unveil the transformative impact of industrial laser solutions on business performance, highlighting their vital role in shaping the industry’s future.

Embark on a journey where technological advancements elevate quality and success standards, shaping the fabric of steel fabrication businesses.

Key Takeaways

- Laser technology enhances accuracy and precision in cutting, welding, and engraving processes.

- Implementing industrial laser solutions increases efficiency by reducing processing times and material wastage.

- Workplace safety is improved through minimized manual intervention in hazardous tasks and automated safety features.

- Versatile laser technology caters to various customer demands and allows for working with different materials and shapes effectively.

Challenges in Steel Fabrication Industry

In the realm of steel fabrication, challenges persist as intricate processes demand meticulous precision and unwavering attention to detail. One of the primary obstacles faced by steel fabrication businesses is ensuring the accuracy of measurements and cuts. The slightest miscalculation can lead to significant errors in the final product, resulting in costly rework and delays in project completion. This underscores the critical need for advanced industrial laser solutions that offer precise cutting capabilities to meet the industry’s stringent requirements.

Moreover, the steel fabrication industry grapples with the challenge of maintaining consistent quality standards across all phases of production. From material selection to welding and finishing, each step must adhere to strict quality control measures to ensure the structural integrity and durability of the final product. Implementing industrial laser solutions can help streamline these processes by automating repetitive tasks, reducing human error, and enhancing overall efficiency.

Benefits of Industrial Laser Solutions

The seamless integration of industrial laser solutions in steel fabrication processes revolutionizes the industry’s precision standards and operational efficiency. Industrial laser solutions offer a myriad of benefits that significantly enhance the steel fabrication business.

One key advantage is the unparalleled precision achieved through laser technology, ensuring accurate cutting, engraving, and welding operations. This precision leads to higher quality end products, reducing material waste and rework, ultimately improving the bottom line for businesses.

Additionally, industrial laser solutions enable faster processing times compared to traditional methods, increasing production capacity and meeting tight deadlines with ease. The versatility of laser technology allows for intricate designs and complex shapes to be achieved with utmost accuracy, catering to a wide range of customer demands.

Moreover, the non-contact nature of laser processing minimizes the risk of material contamination and damage, ensuring the integrity of the final products. Overall, the adoption of industrial laser solutions in steel fabrication brings about efficiency, precision, and quality that are paramount in today’s competitive market.

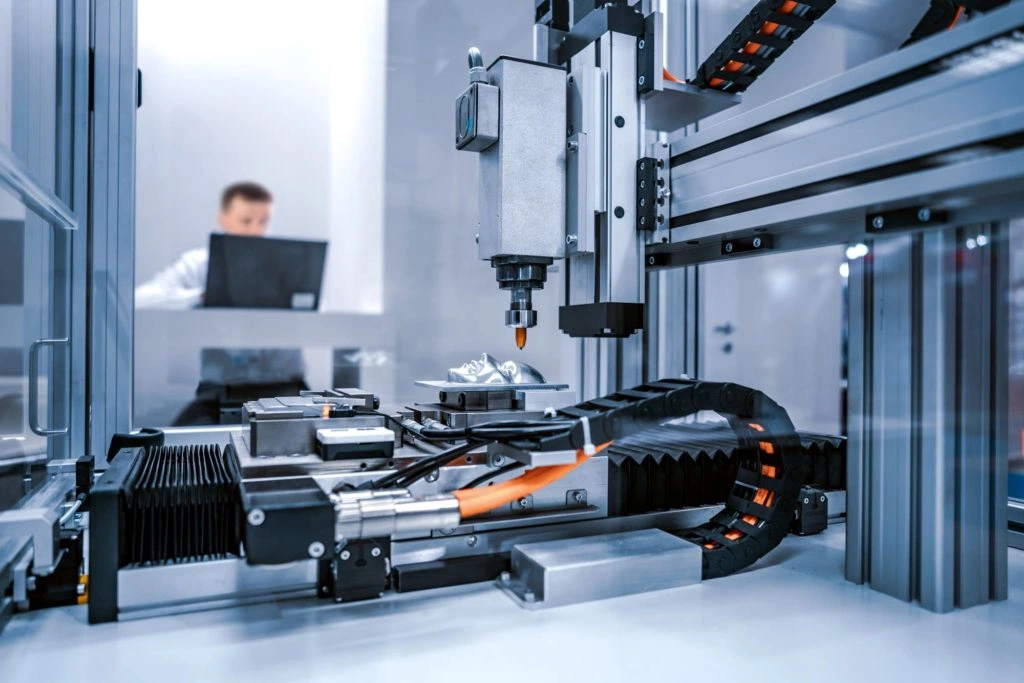

Implementing Laser Technology in Fabrication

Implementing advanced laser technology in fabrication processes enhances precision and efficiency, elevating the standards of industrial production. This cutting-edge technology revolutionizes the way steel fabrication businesses operate, offering a myriad of benefits such as:

- Improved Accuracy: Laser technology enables precise cutting, welding, and engraving, ensuring that each component meets exact specifications.

- Enhanced Speed: By significantly reducing processing times, lasers streamline production workflows, increasing overall efficiency.

- Versatility: Laser systems can work with various materials, shapes, and sizes, providing flexibility in fabrication processes.

- Cost-Effectiveness: While initial investments may be substantial, the long-term savings from reduced material waste and increased productivity make laser technology a cost-effective solution for fabrication businesses.

Increased Efficiency and Precision

Enhancing operational performance through the integration of advanced laser technologies significantly boosts efficiency and precision in industrial fabrication processes. By utilizing industrial laser solutions, steel fabrication businesses can achieve higher levels of productivity and accuracy in their operations.

One key aspect where increased efficiency and precision are evident is in cutting processes. Industrial laser cutting technology allows for intricate designs to be cut with minimal material wastage and high repeatability. This level of precision is essential in ensuring that fabricated parts meet the exact specifications required, reducing the need for rework and enhancing overall productivity.

Additionally, the use of laser welding in steel fabrication results in stronger and more precise welds compared to traditional welding methods. This not only improves the structural integrity of the fabricated components but also reduces the likelihood of defects or weaknesses in the welds.

Enhancing Workplace Safety With Laser Solutions

Incorporating laser safety protocols alongside advanced laser technologies in industrial fabrication processes is crucial for ensuring a secure workplace environment and operational efficiency. Implementing these measures can significantly enhance workplace safety with laser solutions.

- Reduction of Physical Hazards: Laser solutions can minimize the need for manual intervention in hazardous tasks, decreasing the risk of accidents.

- Enhanced Precision: Laser technology offers precise cutting and welding capabilities, reducing the margin of error and the likelihood of workplace injuries.

- Automated Safety Features: Many industrial laser systems come equipped with safety features such as automatic shut-off mechanisms in case of emergencies.

- Employee Training Programs: Providing comprehensive training on laser safety protocols ensures that workers are well-informed and capable of operating laser equipment safely.

Future Trends in Industrial Laser Applications

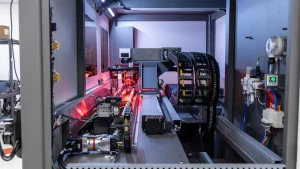

The evolution of industrial laser applications is paving the way for transformative advancements in manufacturing processes. As technology progresses, future trends in industrial laser applications are poised to revolutionize the way steel fabrication businesses operate. One prominent trend is the increasing integration of automation and robotics in laser systems. This integration enhances precision, speed, and overall efficiency in fabrication processes, leading to higher productivity and cost-effectiveness.

Another key trend is the development of advanced laser cutting techniques, such as ultrafast lasers and hybrid laser technologies. These innovations enable more intricate and precise cutting capabilities, expanding the possibilities for complex designs and reducing material waste. Additionally, the rise of additive manufacturing using lasers is reshaping the production landscape, allowing for rapid prototyping and customization of components.

Furthermore, the incorporation of artificial intelligence and machine learning algorithms in industrial laser systems is enhancing predictive maintenance capabilities, optimizing process parameters, and improving overall system performance. These trends collectively indicate a promising future for industrial laser applications, offering steel fabrication businesses the opportunity to stay at the forefront of technological innovation and competitiveness in the market.

Frequently Asked Questions

How Do Steel Fabrication Businesses Address the Challenge of Meeting Tight Deadlines and Maintaining High-Quality Standards?

Steel fabrication businesses meet tight deadlines and uphold high-quality standards through meticulous project planning, efficient resource allocation, and leveraging advanced industrial laser solutions. This strategic approach ensures optimal productivity and precision in their operations.

What Are Some Unexpected Benefits That Steel Fabrication Businesses Can Experience by Adopting Industrial Laser Solutions?

Adopting industrial laser solutions can empower steel fabrication businesses with unexpected benefits like enhanced precision, increased efficiency, reduced waste, and improved safety measures. These innovative technologies revolutionize operations, boosting productivity and elevating overall performance.

Are There Any Common Obstacles That Steel Fabrication Businesses Encounter When Implementing Laser Technology Into Their Processes?

Steel fabrication businesses often face challenges like initial investment costs, training requirements for staff, and integrating laser technology into existing processes. Overcoming these obstacles demands strategic planning, resource allocation, and a commitment to embracing innovation.

How Do Industrial Laser Solutions Contribute to the Increased Efficiency and Precision of Steel Fabrication Operations?

Industrial laser solutions enhance efficiency and precision in steel fabrication operations by offering high-speed cutting, intricate detailing, reduced material waste, and automation capabilities. These advanced technologies optimize production processes, ensuring superior quality and cost-effectiveness.

What Are Some Lesser-Known Ways in Which Workplace Safety Can Be Enhanced Through the Use of Laser Solutions in Steel Fabrication Businesses?

Enhancing workplace safety in steel fabrication businesses using laser solutions involves implementing advanced safety features like beam enclosure systems, safety interlocks, and automated monitoring. These technologies mitigate risks, promote safer work environments, and increase operational efficiency.

Conclusion

In conclusion, the integration of industrial laser solutions in the steel fabrication industry offers a multitude of benefits, including increased efficiency, precision, and workplace safety.

By leveraging laser technology, businesses can enhance their operational wellness and drive productivity to new heights.

As the industry continues to evolve, the adoption of industrial laser solutions will play a pivotal role in shaping the future of steel fabrication enterprises, ensuring sustained success and competitiveness in the market.

You May Also Like: